Lithium-ion polymer batteries are widely used due to their long life and high capacity. However, there are some issues that can arise, such as swelling, unsatisfactory safety performance, and accelerated cycle life attenuation.

Here we will primarily focus on battery swelling and its causes, which can be divided into two categories: the first is a result of a change in thickness of the electrode, and the other is a result of the gas produced by the oxidation and decomposition of electrolytes.

1. The change in thickness of the electrode pole piece

When a lithium battery is used, the thickness of the electrode pole pieces, especially the graphite negative electrodes, will change to a certain extent.

Lithium batteries are prone to swelling after high-temperature storage and circulation, and the thickness growth rate is about 6% to 20%. Of this, the expansion rate of the positive electrode is only 4%, the negative electrode’s is more than 20%.

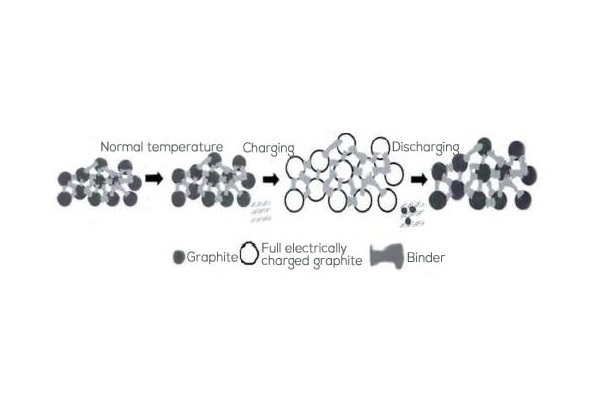

The fundamental reason for the increase in the thickness of the lithium battery pole piece is due to the nature of graphite. The negative electrode graphite forms LiCx (LiC24, LiC12, LiC6, etc.) when lithium is inserted, and the lattice spacing changes, resulting in microscopic internal stress and an expansion of the negative electrode.

The figure is the schematic diagram of the structure change of the graphite anode plate in the process of placement, charge, and discharge

The expansion of graphite negative electrodes is mainly caused by irreversible expansion after lithium insertion. This part of the expansion is mainly related to the particle size, the adhesive, and the structure of the pole piece. The expansion of the negative electrode causes the core to deform, which in turn causes the following: a cavity between the electrode and the diaphragm, micro-cracks in the negative electrode particles, breaking and reorganizing of the solid electrolyte interface (SEI) membrane, the consummation of electrolytes, and deterioration of the cycle performance.

There are many factors that affect the thickness of the negative pole piece although the properties of the adhesive and the structural parameters of the pole piece are the two most important reasons.

The commonly used bonding agent for graphite negative electrodes is SBR. Different bonding agents have different elastic modulus and mechanical strength and have different effects on the thickness of the pole piece. The rolling force after the pole piece is coated also affects the thickness of the negative pole piece in battery use.

When the amount of SBR added is inconsistent, the pressure on the pole piece during rolling will be different. Different pressures will cause a certain difference in the residual stress generated by the pole piece. The higher the pressure, the greater the residual stress, which leads to physical storage expansion, a full electric state, and an increase in the expansion rate of the empty electric state.

The expansion of the anode leads to the deformation of the coil core, which affects the lithium intercalation degree and Li + diffusion rate of the negative electrode, thus seriously affecting the cycle performance of the battery.

2. Bloating caused by lithium battery gas production

The gas produced in the battery is another important cause of battery swelling. Dependent on whether the battery is in a normal temperature cycle, high-temperature cycle, or high-temperature shelving, it will produce different degrees of swelling and gas production.

According to the current research results, cell bloating is essentially caused by the decomposition of electrolytes. There are two cases of electrolyte decomposition: one is that there are impurities in the electrolyte, such as moisture and metal impurities, which cause the electrolyte to decompose and produce gas. The other is that the electrochemical window of the electrolyte is too low, which causes decomposition during the charging process.

After a lithium battery is assembled, a small amount of gas is generated during the pre-formation process. These gases are inevitable and are also the source of irreversible capacity loss of the battery.

During the first time charging and discharging process, the electrons from the external circuit to the negative electrode react with the electrolyte on the surface of the negative electrode to generate the gas. During this process, the SEI is formed on the surface of the graphite negative electrode. As the thickness of the SEI increases, electrons cannot penetrate and inhibit the continuous oxidation and decomposition of the electrolyte.

When a battery is used, the internal gas production gradually increases due to the presence of impurities in the electrolyte or excessive moisture in the battery. These impurities in the electrolytes need to be carefully removed. Inadequate moisture control may be caused by the electrolyte itself, improper battery packaging, moisture, or damage to the corners. Any overcharge and over-discharge, abuse, and internal short-circuiting will also accelerate the gas production rate of the battery and cause battery failure.

In different systems, the degree of battery swelling is different.

For instance, in the graphite anode system battery, the main causes of gas swelling are the SEI film formation, excessive moisture in the cell, abnormal chemical conversion process, poor packaging, etc.

In the lithium titanate anode system, battery swelling is more serious. In addition to the impurities and moisture in the electrolyte, lithium titanate cannot form an SEI film on its surface like a graphite-anode system battery to inhibit its reaction to the electrolyte.

If you are interested in good quality lithium battery products, please don't hesitate to contact us at any time !